Embracing Industry 4.0: Custom Software for Manufacturing Industry Leaders

In the ever-evolving and complex manufacturing landscape, staying ahead of the curve is no longer just an aspiration; it’s an imperative.

The fourth industrial revolution, often called Industry 4.0, is reshaping how businesses operate. This change leaves many industry leaders wondering how they’ll start to embrace this transformative era.

If that sounds like you, keep reading as we delve into the significance of Industry 4.0. Most notably, how custom software solutions can empower industry leaders to not only survive but thrive in the digital era:

The Essence of Industry 4.0

Industry 4.0 is a term that describes the ongoing transformation of manufacturing and industry. It involves the integration of digital technologies, automation, data exchange, and advanced analytics.

This shift is significant because it changes how products are designed, produced, and delivered. At its core, it revolves around automation, data exchange, IoT (Internet of Things), cloud computing, and artificial intelligence.

When integrated seamlessly, these pillars have the power to revolutionise the manufacturing sector. Let’s jump into it:

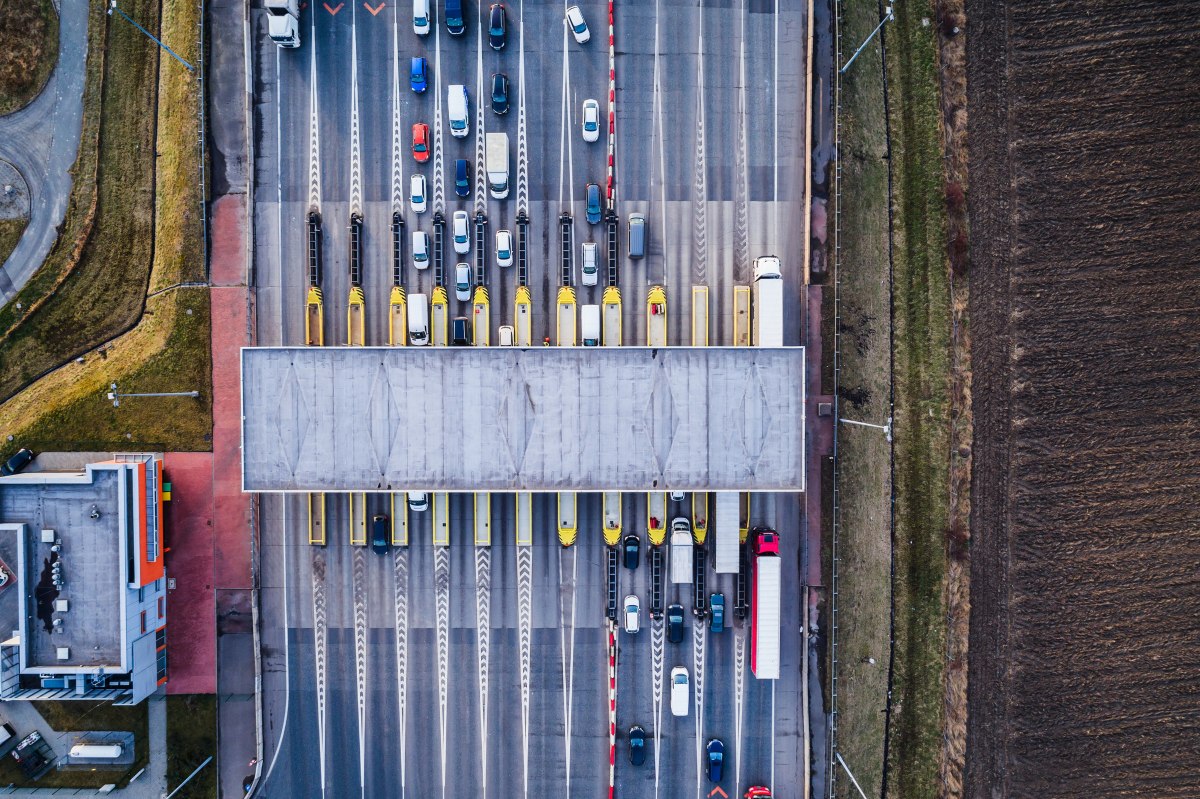

Automation: The Heartbeat of Efficiency

Automation has become an integral part of Industry 4.0, as it enables machines and systems to operate with minimal human intervention.

Automated manufacturing processes offer faster and more efficient production while also providing consistent and reliable results.

This helps manufacturers to reduce errors, improve production throughput, and allocate human resources to more strategic tasks.

Data Exchange and IoT: Fueling Informed Decision-Making

As technology advances, data exchange and IoT have become essential tools for manufacturers looking to optimise their production processes.

By seamlessly connecting devices and systems, manufacturers can gather real-time data from different stages of production, giving them valuable insights into their operations.

This information allows them to make informed decisions, predict maintenance needs, reduce downtime and improve efficiency.

With these tools, manufacturers can focus more on strategic tasks while achieving faster, more consistent results.

Cloud Computing: The Bridge to Scalability

In today’s fast-paced business environment, cloud computing has become an essential tool for manufacturers.

It provides a scalable and cost-effective way to store and process large volumes of data, making it easier for businesses to access critical information and applications anywhere and at any time.

With cloud-based solutions, manufacturers can foster collaboration and agility among their teams, enabling them to work more efficiently and effectively.

Additionally, cloud technology offers enhanced security measures to protect critical manufacturing data from potential threats, giving businesses peace of mind knowing their information is safe and secure.

Overall, cloud computing is a valuable resource for manufacturers looking to streamline their operations and boost their bottom line.

Artificial Intelligence: The Brainpower Behind Insights

Artificial intelligence is a game changer in data analysis.

With machine learning algorithms, businesses can uncover hidden patterns, gain predictive insights, and automate complex decision-making processes.

This technology is instrumental in quality control and production planning.

Additionally, AI-powered manufacturing systems can predict equipment failures before they occur, resulting in lower maintenance costs and reduced downtime.

The Role of Custom Software in Industry 4.0

While the concepts of Industry 4.0 are intriguing, it’s essential to understand that their full potential can only be realised with the right tools in place.

This is where custom software solutions come into play.

Custom software tailors technology to the specific needs of your manufacturing operation, ensuring a seamless integration of Industry 4.0 components.

Here’s how custom software empowers manufacturers:

1. Supply Chain Management

Efficient supply chain management is a crucial aspect of timely production and delivery.

Integrating custom software into your supply chain processes lets you gain real-time visibility into inventory levels, demand forecasts, and supplier performance.

This enables you to make data-driven decisions, optimise logistics, and ultimately reduce costs. Taking advantage of technology to streamline your supply chain can make a significant difference in the success of your business operations.

2. Production Planning

Custom software for manufacturing streamlines production planning by automating the scheduling of machines and personnel.

Analysing real-time data ensures that production is optimised for efficiency, minimises lead times, and reduces the likelihood of production bottlenecks.

3. Inventory Control

Accurate inventory control is a challenge for many manufacturers. Custom software tracks inventory levels, provides alerts for restocking, and optimises inventory allocation based on demand patterns.

This results in reduced carrying costs and minimised waste.

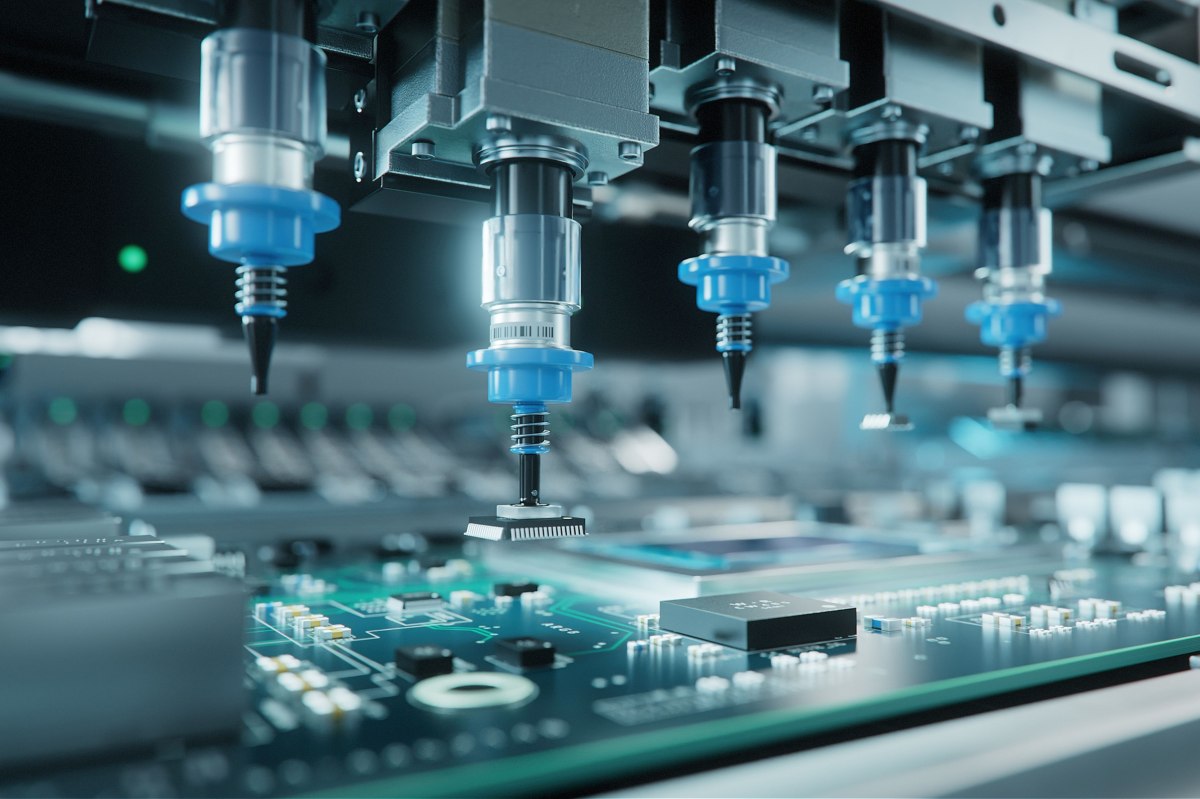

4. Quality Assurance

Maintaining product quality is non-negotiable.

Custom software can incorporate quality control checks throughout production, ensuring that each product meets your defined standards.

Any deviations are flagged, allowing for immediate corrective action.

5. Predictive Maintenance

We all know downtime is costly.

Custom software for manufacturing, combined with IoT sensors, can predict when equipment will likely fail.

By scheduling maintenance proactively, you can prevent unplanned downtime, extend equipment lifespan, and reduce maintenance costs.

6. Integration and Real-Time Visibility

Custom software acts as the glue that binds various systems together.

It facilitates seamless data exchange between machines, devices, and software platforms, providing real-time visibility into your manufacturing process.

This integration fosters better collaboration and data-driven decision-making.

Overcoming Concerns and Misconceptions

It’s natural for industry leaders to have concerns about adopting custom software.

Common concerns include the perceived high cost of implementation and the complexity of integrating existing systems.

However, it’s crucial to recognise that the long-term benefits far outweigh these initial challenges.

To overcome these concerns:

ROI Analysis

Conduct a thorough return on investment (ROI) analysis to quantify the benefits of custom software, including cost savings, increased productivity, and revenue growth.

Engage with Experts

Partner with a reputable software development agency with experience in manufacturing. They can guide you through the process and ensure a smooth implementation.

Focus on Scalability

Custom software is scalable, so think about how you can start small and expand gradually as your business needs evolve.

Get Training and Support

Invest in training and ongoing support to ensure that your team can maximise the value of the custom software.

The Path Forward: Embracing Innovation

In conclusion, Industry 4.0 is not a distant future. It’s here, and it’s transforming the manufacturing landscape.

Industry leaders who embrace custom software solutions as a strategic imperative gain a competitive edge, drive innovation, and future-proof their manufacturing operations.

So, the question is not whether to embrace Industry 4.0 and custom software but when. The future of manufacturing is digital, and the time to innovate is now.

By doing so, you’ll position your company as an industry leader, ready to thrive in the age of Industry 4.0.

Have a project in mind?

Contact the custom software team at Vector today.

Ready to streamline your software solutions?

Let’s dive in together. Get expert consulting from our seasoned engineers.

by

by