According to Statista, the global logistics industry was valued at $9.41 trillion in 2023. Logistics costs account for the lion’s share of any product’s price tag, making them the leading expense for every consumer worldwide. There’s some good news, though—effective management can reduce these “travel expenses” to make basic goods more affordable in all logistics areas.

McKinsey’s survey shows that 87% of shippers have reported either maintaining or boosting their technology investments since 2020. Moreover, 93% plan to sustain or escalate their innovation spendings in the next three years. This trend follows a very simple logic: emerging tech can get items to their destinations faster, cheaper, and more efficiently.

In this article, we’ll explore the key functions of logistics management, check out the top 6 supply chain functional areas, analyze the logistics management benefits, and advise you on how to choose a logistics software provider. Read on for more!

Benefits of Logistics Management

Effective logistics management is key to increased profits. Based on our engineers’ personal experience and what our partners have to say, we’ve formulated the core arguments for this thesis.

1. Best Materials from All Sources

One of the leading functional areas of supply chain management is ensuring your business can source the highest-quality materials from different suppliers. Partnering with various industries and manufacturers helps you broaden your resource pool.

Imagine a company that specializes in outdoor gear. With advanced logistics management, it can pinpoint the top suppliers for products like tents, backpacks, and sleeping bags. By utilizing e-sourcing platforms, the company also can scout promising suppliers, assess their capabilities, and strike the best deals.

Effective logistics management means your company gets everything required on time, in optimal condition, and at relevant costs. Currently, this sophisticated system is almost a prerequisite to remaining competitive in the market.

2. Optimized Transportation

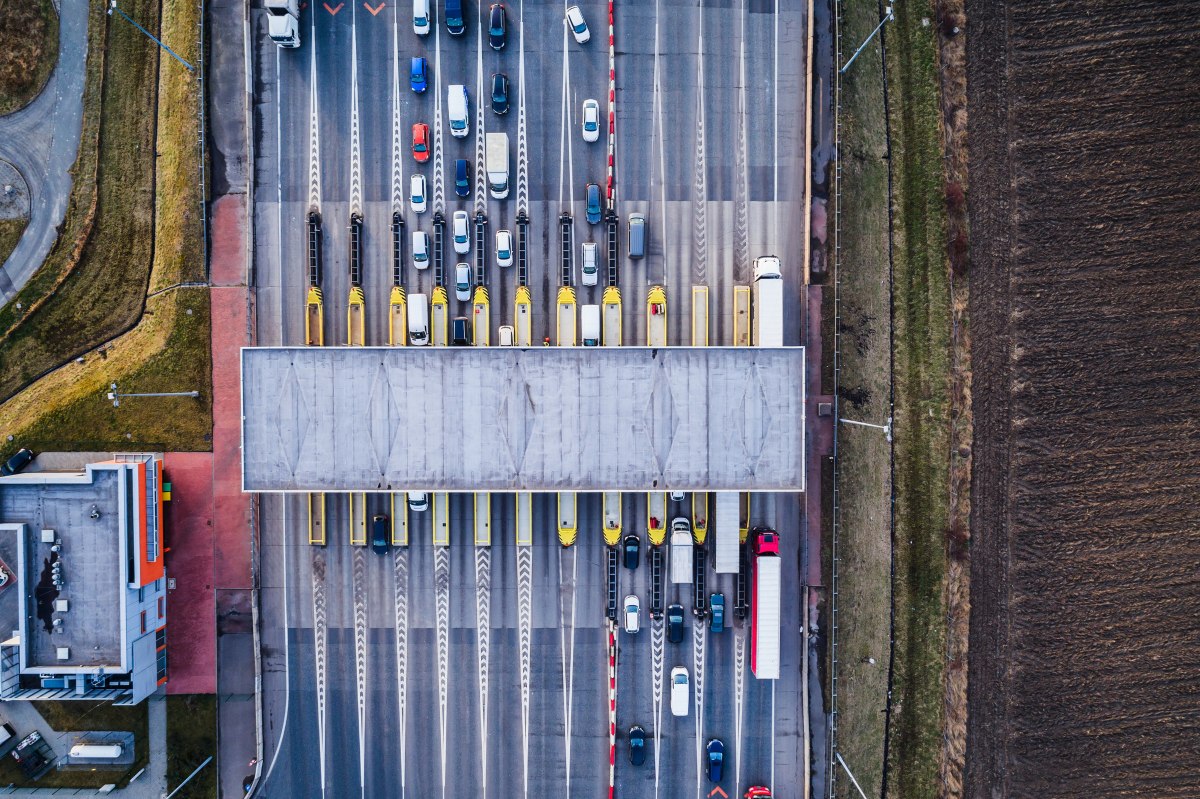

Optimized transportation is one of the critical logistics parts of a business. Companies analyze various factors, such as delivery routes, types of transportation, carrier performance, and many others, to ensure their goods are shipped on time and safely.

This is also included as one of the benefits of custom logistics software, ensuring you get fuel-efficient routes that help you complete all shipments on time. For instance, specialized software allows companies to effortlessly combine air and sea freight to balance speed and costs when shipping internationally. This strategy reduces transit times, minimizes fuel consumption, and lowers overall transportation costs, leading to a more cost-efficient supply chain.

3. Improved Inventory Management and Demand Forecasting

According to Gartner, 50% of supply chain organizations will invest in AI-powered applications and advanced analytics through 2024. The combination of AI and ML will likely allow companies to quickly solve any logistical challenges they may face. That’s why AI-powered logistics software is quickly becoming one of the biggest trends in this industry.

AI inventory management also reduces:

- Holding costs;

- Risk of stockout;

- Risk of overstock.

Effective demand forecasting is among the most essential functions of logistic management, and can be vastly improved by introducing AI-powered prediction algorithms. This tech also allows businesses to plan promotions and sales strategies more effectively, aligning inventory levels with anticipated customer demand. In perhaps the most classic example, you can analyze demand for products in different sectors during the Black Friday sale to optimize your promotion and supply operations.

4. End-to-End Visibility

Advanced software can provide a company with real-time insights into every stage of the supply chain.

It also facilitates:

- Improved decision-making;

- Fast issue resolution;

- Improved coordination;

- Quality control;

- Cost reduction;

- Improved risk management, and more.

A high level of transparency is also crucial for maintaining compliance with regulations and meeting customer expectations. Certain products require specific transportation conditions, and monitoring their temperature and conditions in real time may be necessary to ensure they’re fit to be sold. This is a massive step toward meeting your customers’ needs more consistently, which has a massive effect on any company’s brand image.

5. Intelligent Route Planning

Route optimization significantly lowers transportation costs like fuel expenditure, leading to increased profits. Combining big data and analytics allows companies to consider traffic conditions, weather, delivery schedules, and other rapidly shifting factors to plan their transportation accordingly.

Intelligent route planning also makes a company more reliable as a partner and supplier by ensuring that deliveries are always made on time. By continuously analyzing and adjusting routes based on local conditions, businesses can maintain high levels of customer satisfaction and operational efficiency.

6. Higher Profits

The top 10 logistics companies generated revenue of around $538 billion in 2021, and a large percentage of that sum is a result of high-quality management and planning. Companies that conduct logistics using big data and specialized software save money on transportation, inventory management, and supply chain management. Access to advanced data allows these logistics giants to avoid extra costs at all stages of their operations.

Top 6 Areas of Logistics Management

Let’s check out the leading areas of logistics management and their features.

Order Processing

Order processing is the first step for any logistics company and is usually conducted by the sales team. This includes order entry, verification, and fulfillment.

Here’s what order processing typically includes:

- Analyzing the order to ensure all terms are agreed upon.

- Providing information on prices, delivery times, payment methods, and schedules.

- Providing information on the availability of items in stock.

- Planning for the possible material shortage.

- Indicating any specific features of the order.

These steps are a generalized image of what logistics companies do: they may vary depending on your industry, situation, and many other factors.

Inventory Management

Approximately 34% of businesses unintentionally sell products currently unavailable in their inventory, resulting in delayed or canceled order shipments. That’s why it’s necessary to consistently monitor and maintain the right balance of stock.

Inventory management includes:

- Tracking items for later shipment;

- Forecasting demand;

- Managing stock replenishment.

Inventory handling also involves making individual products and their categories easy to find in physical storage spaces. AR technologies are a current trend for solving this kind of challenge, making order management faster and more convenient.

Warehousing

Warehousing plays a gigantic role in the logistics management process by providing storage for goods until they are distributed. Efficient warehousing requires:

- Optimal layout design;

- Inventory organization;

- Automated storage and retrieval systems.

For example, global corporations like Samsung maintain a strong worldwide presence thanks to multiple warehouses across priority regions.

Transportation

Transportation is a core component of logistics. Transportation management involves:

- Selecting the most efficient means of transportation;

- Route planning;

- Carrier management.

This is where the major part of the price for most products is formed, as fuel is currently far from the most affordable resource. A historical price chart shows this.

Packaging

Packaging is an essential area of logistics that ensures products are protected during transit and storage. There are two types of packaging:

- The one that customers see on the shelf.

- The one that transportation companies use.

Proper packaging involves choosing the best materials and designs to protect the goods from potential damage and optimize storage space. It’s also an effective way to enhance your brand’s image and customer experience, as 72% of Americans stated their purchase decisions were influenced by a product’s packaging design.

Monitoring

Monitoring is essential for maintaining end-to-end visibility and control over the logistics process. It includes multiple elements:

- Real-time shipment tracking;

- Inventory levels tracking;

- Supply chain performance analysis;

- Fleet management, and more.

This often includes using IoT, GPT, data analytics, and other examples of advanced tech. Effective monitoring is your company’s key to swiftly identifying and resolving potential issues.

Streamlined Success in Action: Vector Software

Logistics is a field that directly sustains most of the modern industries. Therefore, even while developing digital solutions for other domains, we have also implemented solutions directly related to logistics tasks.

The most widely used software in the Norwegian construction industry, SmartDoc, includes modules for inventory and equipment management, tracking of resource and material consumption, transportation, and reserves. The launch of an application that included not only traditional construction functions but also the ability to monitor the supply and availability of materials and resources was a real revolution for the industry.

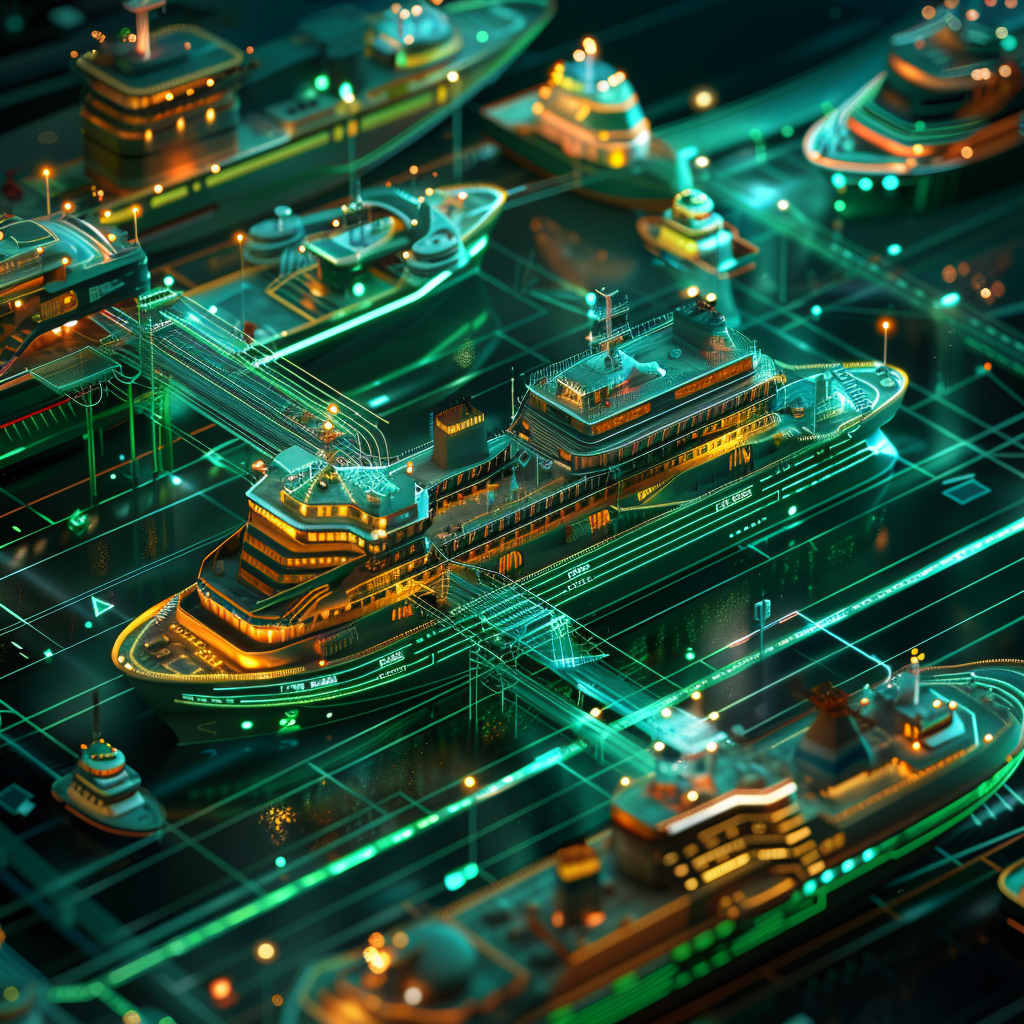

Managing inventory in a warehouse is no more challenging than working vessels in the vast ocean; Vector Software has successfully upgraded its existing vessel management system, VISSIM, to help the platform continue to track and manage the movement of vessels traveling across the global ocean.

Similarly, products within a warehouse can be easily tracked and managed using custom software, ensuring that each product is tagged, stored, and delivered to the appropriate logistics area according to the business requirements.

Final Thought

Logistic management is a complex process with lots of essential components. Thus, companies that can utilize cutting-edge technologies to improve their operation beyond the capabilities of traditional management methods typically outpace the competition. Partnering with a custom software solutions development company like Vector Software can help you build top-tier logistics software for your business and leverage all its benefits. Book a call now!

FAQ

What is the role of logistics in supply chain management?

Logistics includes multiple elements, such as transportation, warehousing, inventory management, order processing, and more. These processes help reduce costs and improve delivery times. Seamless coordination of these activities is the main role of logistics in supply chain management.

What is logistics management?

Logistics management is the process of planning, implementing, and controlling movement and storage of goods. It includes everything from sourcing the product to delivering it to customers.

How can Vector Software help me with custom logistics solutions development?

Vector Software’s team offers over 10 years of experience in creating custom solutions across all industries. You’re guaranteed to get cutting-edge software that meets your business demands and will assist you in increasing profits.

Ready to streamline your software solutions?

Let’s dive in together. Get expert consulting from our seasoned engineers.

by

by