In warehouse management, efficiency and precision are not just goals—they’re necessities. The ability to deliver products to customers promptly is the cornerstone of your business’s success. That’s where a robust logistics management system comes into play, seamlessly integrating the six vital functions of your logistics operations: order processing, transportation management, inventory control, warehousing, packaging, and material handling.

By integrating custom software solutions into your business, you’re not just upgrading your processes; you’re elevating your service quality, ensuring every customer interaction is a testament to your commitment to excellence. Let’s step into the future together and redefine logistics management. Your journey towards a more efficient, error-free logistics system begins now:

The Power of Custom Software

Let’s explore this from the Norwegian market perspective. The logistics market is expected to grow to USD 45.46 Billion by 2029. This is because Norway has been one of the earliest Internet adopters. This is why major e-commerce companies are looking to set up multiple warehouses in smaller towns closer to the large cities. Consequently, it means that they will need better warehouse management tools to ensure good visibility into all the inventory in each warehouse.

Enhancing Security

Most warehouses handle multiple types of products; in these types of warehouses, keeping track of each item becomes very challenging. Businesses can now use industry 4.0 techniques like connected devices and cloud-based platforms to improve safety at the warehouse. Imagine tracking the number of products available in each box using QR codes or camera-based tracking, which ensures that each product placed or removed in a package can be followed.

Reducing Costs

The challenge with cold storage warehouses is the constant movement of products, making it difficult to manage the temperatures continuously. If not managed properly, this could lead to many losses for the cold storage business.

Whereas, custom software helps support warehouse management by using data-driven practices. For example, you can automatically change the temperature of each section of the cold storage warehouse depending on the data regarding the product being stored. Such real-time monitoring can prevent spoilage and damage, especially in cold storage warehouses where even minor fluctuations in temperature or humidity can have significant impacts

Driving Productivity

Businesses require logistics businesses to provide them with complete end-to-end visibility of when a product reaches the warehouse when it leaves the warehouse, and when it comes to the end customer. Although, it’s becoming challenging for businesses to provide this level of visibility to every customer they serve with their warehousing business.

According to SupplyChainDive, a staggering 94% of businesses do not have full visibility of their supply chain and logistics operations. This statistic underscores the widespread challenges of logistics regarding supply chain visibility, which can impact business revenue, efficiency, productivity, and customer experience

Luckily for these businesses, industry 4.0-based solutions and blockchain-based solutions can enable warehousing businesses to showcase the exact location of each product at any given time to their customers, improving the customer’s productivity and providing them with a better experience.

How Vector Software Solves Logistics Challenges

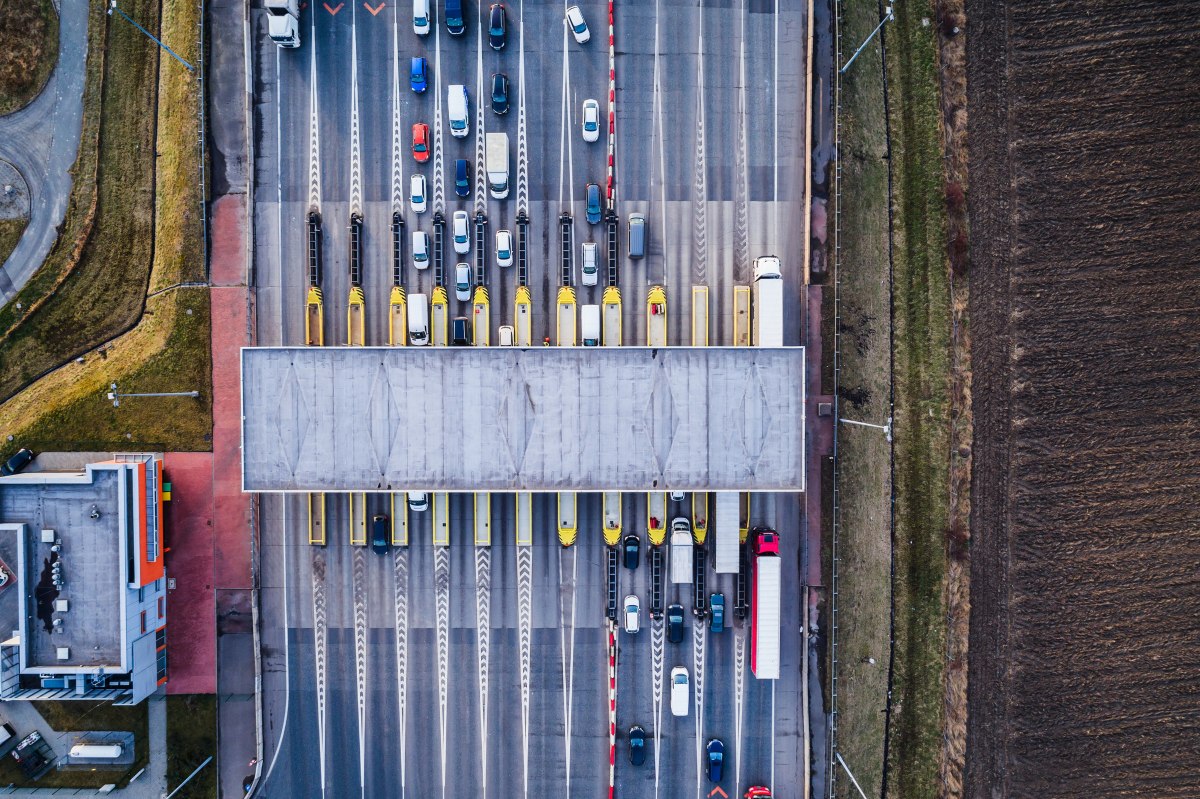

We worked with Øresund Bridge to manage the traffic movement and process the toll payment. While working on this project, we implemented the best security protocols as the process required AI-based cameras which could identify the vehicle and number plate and then check their accounts to deduct tolls.

This process starts 150m before the toll booth, meaning no vehicle stops at the toll for more than a fraction of a second. The ones who do not have enough funds to deduct from their account must pay the amount at the toll booth (which was processed quickly by the system built by Vector Software). This saved the toll booth management a lot of money, which they would have had to spend on traffic management.

Preparing for The Future of Warehouse Management

Ultimately, by implementing custom software, you can revolutionise the way you track and manage product movements within your facilities. These systems are capable of not just tracking movements but also identifying different types of products. This capability goes beyond mere inventory management; it introduces a level of precision and efficiency previously unattainable.

Imagine a warehouse where every item is accounted for, and its journey through your facility is tracked with pinpoint accuracy. This isn’t just about avoiding misplacement or loss; it’s about optimising your entire operation. From storage to dispatch, every process can be streamlined and enhanced.

Vector Software stands out as a great business partner who have standard processes for quality control (ISTQB) and project management (ISO 9001:2015). These are not just accreditations. They are proof of our methods work, and work well.

Have a project in mind?

Speak to our expert team at Vector Software

Ready to streamline your software solutions?

Let’s dive in together. Get expert consulting from our seasoned engineers.

by

by