Do you remember the Ever Given debacle? We’re talking about that case with a ship running aground in the Suez Canal in 2021 and blocking one of the world’s most used sea-based logistics routes for a considerable time. This resulted in delays for many shipments from Asia to Europe and vice versa. The blockage greatly impacted global trade, with about $9.5 billion worth of goods affected each day.

Logistics businesses must deliver products to their destinations at the right time and in the proper condition to stay competitive, and such situations are only one of the many potential issues they must face.

Read on to learn about the challenges of logistics and ways to mitigate them.

Top 5 Logistic Challenges for Businesses

Let’s examine the biggest problems faced by logistics companies in the modern world. These logistics challenges have been common for quite a while, but only a few businesses have managed to overcome them effectively.

Challenge 1: Inefficient Transportation Management

Transportation management is a basis of any modern logistics ecosystem. Delays and complications are sadly inevitable, but those should be handled properly to avoid further issues. For this purpose, logistics businesses employ various monitoring and management systems. However, those applications often struggle to fully cover the business needs of a company, and can create complications of their own.

One option to avoid this is using custom software. For instance, if you struggle with effective route planning, such systems can take into account factors like weather and traffic to do the job for you.

Fleet management is another significant and widespread transportation issue that digitization can solve. Custom solutions can track locations and monitor shipments, vehicle maintenance, and driver assignments, as well as predict the needs of your fleet using big data analysis.

Challenge 2: Inventory Management Woes

Inventory management is crucial for taking full advantage of regular shifts in demand. However, for this strategy to be effective, you’ll need the complete support of your manufacturing and logistics partners. If any of these parties fail to deliver on their commitments, your business can suffer enormous losses.

The biggest challenge in inventory management is replenishing it in time. Companies must collaborate with their logistics partners to avoid stockouts while also preventing overstock.

Challenge 3: Warehouse Management Complexities

All product-based businesses employed warehousing to store their inventory since time immemorial. However, the modern industry standards place a lot of pressure on delivery speed, and that has a profound effect on warehouse management.

This means businesses can no longer have a central warehouse and ship products from there. Today, companies must have multiple bases of operation spread around their target regions and carefully manage stock for all of them, making warehousing many times more difficult.

In addition, the ever-increasing globalization creates new warehouse management issues that logistic companies have to solve to stay on the market.

Challenge 4: Order Fulfillment Bottlenecks

Order fulfillment is a series of processes that are set in motion once a customer orders a product from a business. These include checking the inventory for the product in the nearest warehouse, packaging the product, identifying the correct logistic partner, and ensuring accurate delivery.

Have you ever ordered something and received something else? That’s a deficiency of the order fulfillment process, and issues like this discourage many Norwegian consumers from choosing payment options like Cash on Delivery. These inefficiencies are also notoriously difficult to interact with, as tracking the exact movement of an individual product through the order fulfillment process is exceedingly difficult.

Challenge 5: Inaccurate Demand Planning

This point is tied to inventory management, and highlights how warehousing is more than just the physical planning of where to store goods and how to move them. Demand prediction means ensuring your stores have the necessary goods to capitalize on the changes in consumer behavior, both seasonal and otherwise.

Inefficiencies in demand planning can result in lost profits and brand reputation damage.

The solution to these challenges lies in better data analytics through solutions tailored to your business. These applications can gather data about your potential customers, helping you plan your demand, inventory, and warehousing more effectively.

5 Ways to Overcome Logistics Management Challenges

Solution 1: Custom Transportation Management

Custom software platforms are instrumental in improving efficiency in logistics transportation management. These systems can monitor and manage transportation, tracking vehicles in real-time to ensure complete transparency of the delivery process from source to destination. They also help manage fleet operations, including vehicle maintenance and driver management.

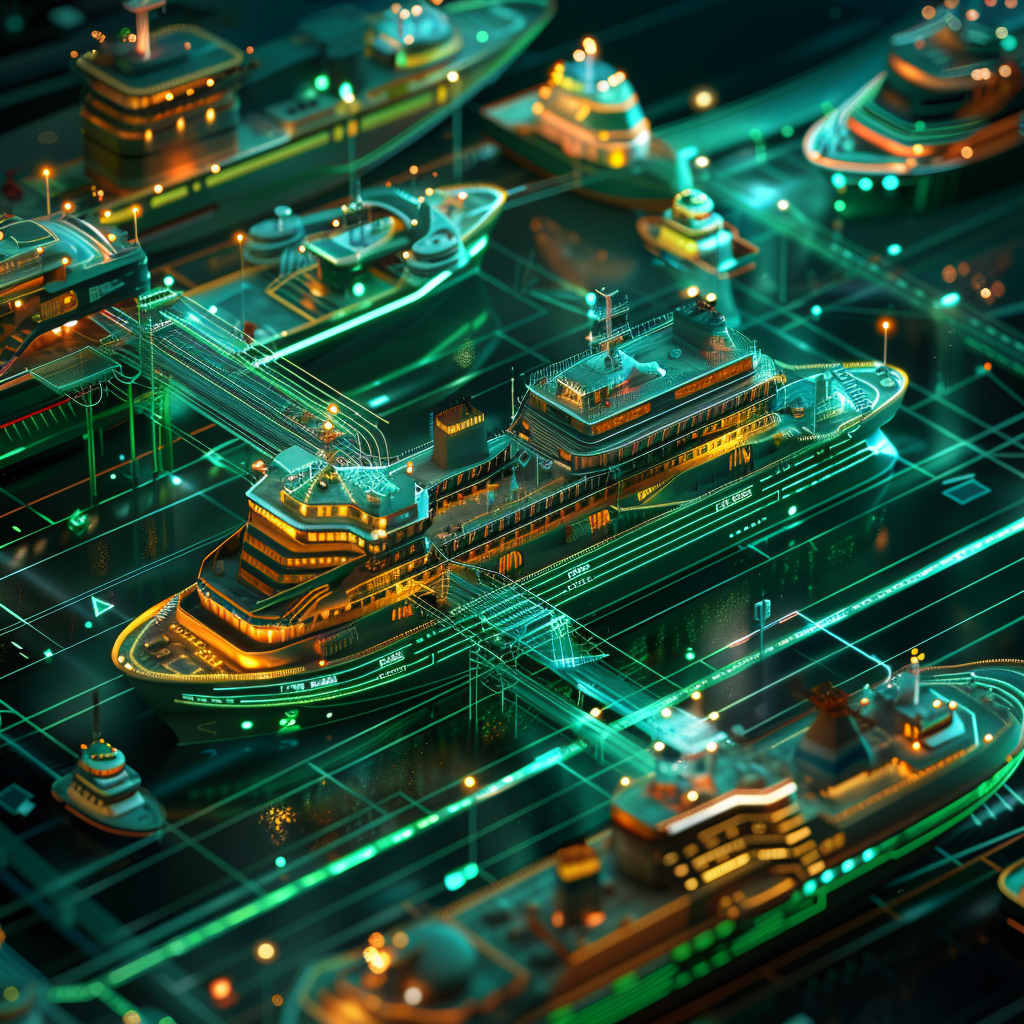

For instance, VISSIM can track over 200,000 vessels in real time. It’s primary functions include:

- Vessel location tracking;

- Personnel location tracking;

- Port management;

- Emergency prediction.

Such software is essential to mitigate the most significant challenges in logistics that emerge from a lack of information. It’s critical to monitor your vehicles’ status to ensure they are operating at maximum efficiency.

Solution 2: Data-Driven Inventory Management

Businesses should closely collaborate with their partners to maintain a balance between running out of stock and inventory overstocking. Custom software allows you to analyze sales data to optimize inventory levels and plan timely stock replenishment.

These solutions can contribute the following:

- Automated reordering helps maintain optimal stock levels by generating purchase orders when inventory falls below a certain threshold;

- Real-time inventory tracking provides businesses with up-to-date information on stock levels, locations, and movement, facilitating better decision-making;

- Predictive analytics leverage historical data and market trends to forecast future demand, allowing businesses to adjust their strategies.

While there are lots of extra features you can add, these are the main options to mitigate the leading challenges in logistics management using data. Vector Software’s team can help you build a similar solution and experience the benefits of custom logistics software for yourself.

Solution 3: Real-Time Warehouse Management

Custom software solutions provide a real-time view of inventory availability across several warehouses, tracking product movements to enhance efficiency and traceability on a global scale.

These solutions can include:

- Barcode scanning and RFID tracking reduce human error and improve traceability by automating the key elements of inventory management;

- Automated storage and retrieval systems (AS/RS) can manage the storage and retrieval of goods, increasing warehouse efficiency and reducing labor costs;

- Integration with transportation management systems (TMS) streamlines the coordination between warehousing and transportation to keep your deliveries timely and accurate.

If you’re wondering how to overcome logistics challenges related to warehouse management, these solutions are your best bet. Once again, Vector Software experts can help you integrate these features into your business at minimal cost.

Solution 4: Order Management

Custom software can speed up order fulfillment by tracking each product through the entire process. These applications can also incorporate an order processing automation system.

- Order verification ensures that the correct items are picked and packed, reducing the risk of incorrect deliveries;

- Automated picking lists guide warehouse staff to the precise locations of the needed items, accelerating the picking process;

- Integrated shipping solutions can automatically select the best shipping options based on cost, speed, and customer preferences.

Vector Software team can assist you in addressing order fulfillment logistics bottlenecks and ensure you’ll receive a high-quality software solution.

Solution 5: Data Analytics Software

Businesses can use advanced data analytics to gather insights about demand, which enables more advanced inventory and warehousing strategies. These solutions incorporate demand forecasting tools that use machine learning algorithms to analyze historical sales data, market trends, and external factors.

Identifying patterns and predicting future demand can reduce the risk of stockouts or overstocking. Additionally, integrating these tools with other systems, such as ERP and CRM solutions, can provide a decent overview of global supply chains, enhancing coordination and improving overall efficiency.

This integration ensures that all departments have access to real-time data, which naturally leads to better communication and decision-making.

Why Vector Software Is Your Eligible Partner for Logistic Software Development

Vector Software is your trusted custom software development partner with over 10 years of experience and a global pool of 160+ professional engineers. We specialize in logistics software development and have all the expertise to bring your ideas to life. Whatever logistics problems your business might be experiencing, we’ve got the tools to improve the situation for you.

Check out our case studies:

- VISSIM

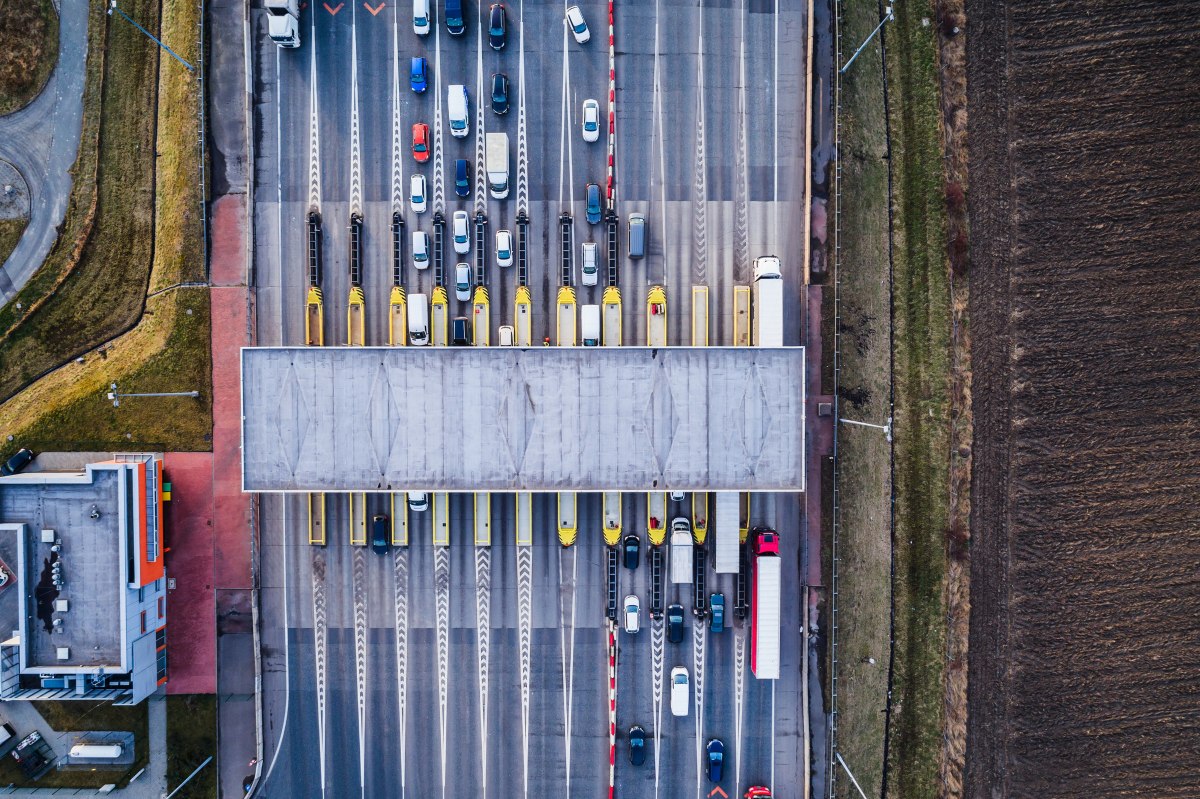

A vessel traffic management system capable of monitoring up to 200,000 vessels in real time; - Øresund Bridge

A real-time tollgate traffic management system with AI vehicle detection and license plate recognition; - Carus Vehicle Classification

An automatic vehicle classification system that works at port check-ins.

Book a call now and start developing your logistics software with real professionals.

Conclusion

While the logistics industry faces numerous challenges, we have highlighted the key issues encountered by most global companies. These efficiency and speed problems can often be resolved relatively easily with custom software solutions. If you are looking to develop such a solution, Vector Software is your ideal partner for this task.

FAQ

What are the challenges in logistics?

The leading challenges in logistics are inefficient transportation management, inventory management issues, warehouse management concerns, order fulfillment bottlenecks, and inaccurate demand prediction. In most cases, these issues can be mitigated by high-quality, relevant software solutions.

What are the functional areas of logistics?

The functional areas of logistics include transportation, warehousing, inventory management, order fulfillment, demand planning, packaging, materials handling, and logistics information systems. These areas are what makes supply chain operations possible.

How to choose a logistics software provider?

If you’re wondering how to choose a logistics software provider, consider these factors before collaboration. Evaluate your potential partner’s industry experience, integration capabilities, user reviews, customer support, and cost-effectiveness. Ensure they offer customizable solutions that cope with your specific logistic challenges before committing to the deal.

Ready to streamline your software solutions?

Let’s dive in together. Get expert consulting from our seasoned engineers.

by

by